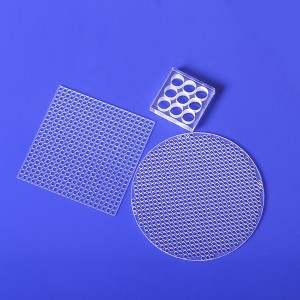

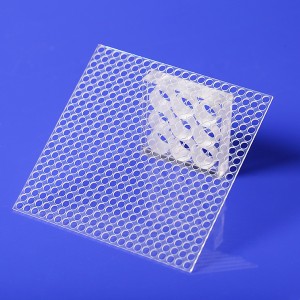

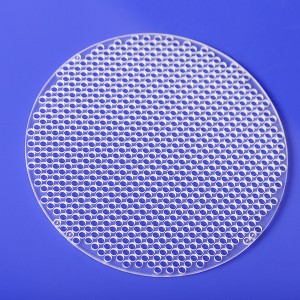

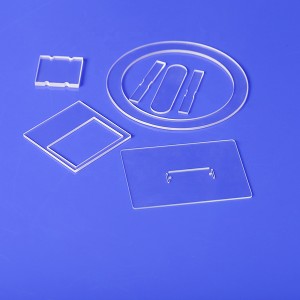

CNC Machining JGS1 Fused Silica plate with hole

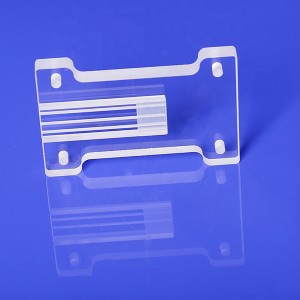

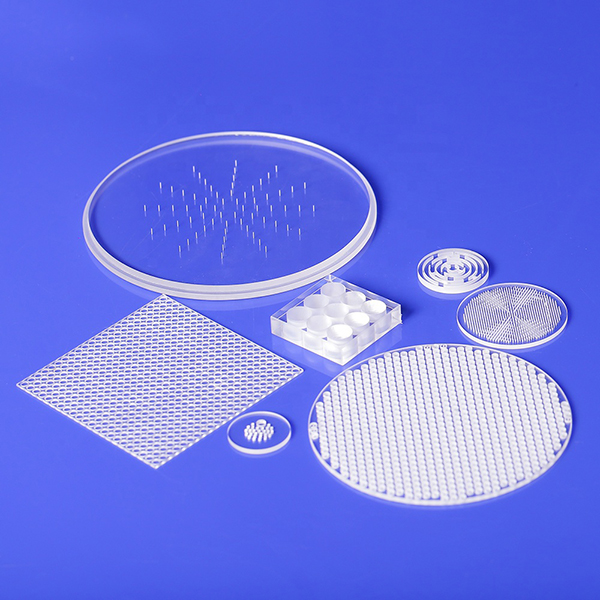

The High Precision of CNC Machined can supply good quartz glass parts, such as slotting, drilling, and beveling. The advantage is that the processing accuracy is high and it can meet the needs of different customers.

1.Custom Design and Tailor-Made are welcomed.

2. Multiple materials like Quartz, Fused Silica, Various Optical Glasses

3.The High-Precision Fabricated Parts deliver Superior Quality and Long Lifespan.

China Optical Quartz Glass Grade

| Name | Corresponding grade | Feature |

| Far Ultraviolet Optical Quartz Glass | JGS1 | Transparent in the ultraviolet and visible spectrum; no absorption band in the 185-250nm band; strong absorption band in the 2600-2800nm band; non-luminous, stable light radiation. |

| UV optical quartz glass | JGS2 | Transparent in the ultraviolet and visible spectrum; no absorption band in the 200-250nm band; strong absorption band in the 2600-2800nm band; non-luminous, stable light radiation |

| Infrared optical quartz glass | JGS3 | Transparent in the visible and infrared spectrum; no obvious absorption band in the 2600-2800nm band; |

Material

UV Fused silica

Schott borofloat 33 glass

Sapphire

Tempered glass

Specification

We can make many kinds of quartz parts according the drawing.Almost all the quartz parts is done by CNC machining,small part is assisted by laser equipment. We operate and offer a wide range of capabilities in processing glass materials.

CNC milling centers with the largest table size being 24” x 36”

CADCAM Water Jet milling centers with a maximum table size of 26” x 52”

Products shown

Applications

Printing and dyeing

Optical windows

Temperature resistance support plates

Pedestals for reaction chambers

Quartz cover plates

Temperature resistant accessories on semiconductor equipment

Vacuum coating equipment accessories

Quartz Characteristic

|

SIO2 |

99.99% |

|

Coefficient of Expansion |

5.54 x 10-7 (K-1) |

|

Strain Point Temperature |

1343 Degree K |

|

Softening Point |

1933 Degree K |

|

Thermal Conductivity |

1.37 W/m 0K |

|

Annealing Point Temperature |

1433 0K |

|

Average Specific Heat – |

771 J/kg.K |

|

Optimal Operating Temperature |

1423 – 1473 0K |

|

Specific Heat Conductivity |

1.48 W/m.K |

|

Acid tolerance |

30 times than ceramic,150 times than stainless |

|

Density |

2.204 g/cm3 |

|

Tensile Strength |

49 N/mm2 |

|

Poisson’s Ratio (No Unit) |

0.17 |

If you’re looking for Machined quartz discs and Machined quartz plates suppliers who can deliver customized and high-quality Machined quartz plates, contact US.